Introduction

Quantum tunneling composites (QTCs) are polymer matrix composites (elastomers) filled with metallic particles and were discovered in 1997 by scientist David Russey while working on the development of conductive adhesives. The surprising properties of this new material led to the creation of Peratec, a company dedicated to the research, application exploration and technological transfer of these materials.

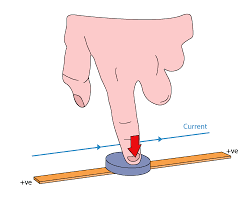

The operating principle of QTC is different from that of other conductive polymers obtained by infiltration (using fillers such as metallic particles, carbon nanotubes, carbon black, etc.). Infiltration attempts to bring charged metallic particles into contact to obtain electrical conductivity or at least significantly reduce the electrical resistance of the polymer matrix [1], [2]. However, QTCs, which are typically obtained by integrating Ni particles of about 100 to 500 nm into an elastomer matrix, behave differently. At rest, these metal particles are not in contact and the polymer acts as an insulator, but when the material is suitably deformed, the particles come together (without actually touching) and the material becomes a better conductor (electrical resistance is reduced by several orders of magnitude).Quantum tunneling composites

Researchers at Durham University provided an explanation for this behaviour ([3], [4]). The Ni particles embedded in the polymer matrix have an irregular surface (in the form of spikes), so when the material is pressed, the particles come together and overcome the “quantum tunnelling” effect (overcoming the non-conducting parts of the polymer between the particles) allowing electrons to “jump” from some particle irregularities to other particle irregularities without the need for contact.Quantum tunneling composites

The more the material is deformed, the greater the reduction in electrical resistance. Thus, the use of elastomeric matrices is particularly effective, although thermoplastic or heat-resistant materials can be used in applications that need to withstand higher pressures.Quantum tunneling composites

One of the main advantages of these materials is that they are insulators at rest, so the electronic components connected to these devices do not consume power unless pressure is applied to them. This minimizes the size of the required power supply system, especially for multipurpose uses related to the development of implantable medical devices [5] and aeronautical devices where the final size is a determining factor [22].Quantum tunneling composites

In addition, these materials are very cheap, easy to obtain and distributed by several companies at very affordable prices (less than 1 euro per sensor), making the final application very similar to other solutions available on the market and not cost-intensive. In fact, in addition to Peratech Ltd., several companies in this field, including QIO Systems Inc., Elek Tek and Elek Sen, are exploiting the functionality of these materials in the electronics industry [6], [7] and the textile industry. [8] It is used in various fields.Quantum tunneling composites

The main proposed applications for these materials in different fields are listed in the appendix. It also refers to researchers, companies, universities or research centers responsible for patenting, testing and other tasks related to these applications, including dissemination, marketing or consulting services. Some of these proposals have already been tested and are in the commercialization stage, such as tactile switches integrated into textiles, various electronic devices and robotic hands, but most of these ideas have not gone beyond the patent stage (some of them are mentioned below).Quantum tunneling composites

In general, the applications listed in the Appendix usually use these materials as “all or nothing” switches due to their ease of design and implementation, but they can also be used for other applications that require quantization. To accelerate (and thus facilitate their expansion in industry), it is essential to characterize and model these materials in detail.Quantum tunneling composites

Other researchers have proposed models based on complex quantum phenomena to explain the electron emission due to the Fowler-Nordheim effect and the Schottky barrier at polymer-metal interfaces [3]. Although they describe the tunneling effect very accurately, they lack sufficient detail to address the physical properties of the material in question and other thermomechanical aspects that influence its ability as a transducer.Quantum tunneling composites

This article includes a detailed description of the constitutive equations to model the behavior of these materials. It is based on the use of a simple quantum model of a particle passing through a potential barrier, together with the influence of the viscoelasticity of the material.Quantum tunneling composites

Materials and methods

As a starting point for a detailed study of this research, the British company “MUTR Teaching Resources” (

www.mutr.co.uk) at Middlesex University (www.mdx.ac.uk, used a small QTC wafer measuring 3.6 mm × 3.6 mm × 1 mm. Although the company also offers these materials in the form of sheets and wires for various applications, here we will use them in the form of wafers suitable for the analysis of a combination of mechanical, thermal and electrical phenomena.Quantum tunneling composites

Sensor used

Feature evaluation test

The tests were carried out at the facilities of the Product Development Laboratory of the Polytechnic University of Madrid, under controlled temperature and relative humidity conditions, at an ambient temperature of 30 °C, using the materials and equipment described above.Quantum tunneling composites

Figure 3, Figure 4, Figure 5 and Figure 6 show the results of these tests and show the performance of the QTC sensor as a function of pressure and application time for tests performed at temperatures of 30, 40, 50 and 60 °C. the electrical resistance changes.

Simplified quantum model: particle crossing a potential barrier

In quantum mechanics, the tunneling phenomenon can be demonstrated by a one-dimensional finite potential barrier problem. This model can also be applied to model the behavior of QTCs when subjected to external thermal and mechanical stimuli in a particularly simple way, as this study shows.

The Schrödinger equation can be used to analyze the behavior of particles across potential barriers, as described in many textbooks [12], [13]. One-dimensional case

Comparison of tests and models.

To test the proposed constitutive equation, the value of the electrical resistance of the QTC sensor must be simulated as a function of variables such as pressure, temperature and load application time, and compared with the variables found in the tests performed. For this purpose, a “Matlab R2007a” assisted program was created to evaluate and represent this equation in the range of interest of the influencing variables.

Conclusion

Quantum tunneling composites (QTCs) are novel polymer-metal composites that have recently become commercially available at affordable prices and are suitable for the development of pressure sensors for a variety of applications. Therefore, it is especially important to focus on characterization and modeling tasks to facilitate the expansion of industrial applications in the coming years.